LIMING VU AGGREGATE OPTIMIZATION SYSTEM———-VS———–TRADITIONAL AGGREGATE MAKING

LIMING VU AGGREGATE OPTIMIZATION SYSTEM

ADVANTAGES

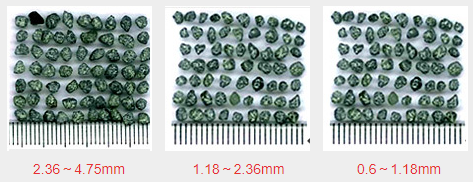

1.Good Particle Shape

The output shape can rival natural sand (Real product rate can be 58%-59%).

2.36~4.75mm1.18~2.36mm0.6~1.18mm

2.Low Consuming Cost

New innovated technology combines performance and technology of equipment reasonably, realizes low consuming cost.

3.Adjustable Fineness

The fineness is adjustable easily (2.2-3.2).

4.Precise Grading

The grading is more precise than before. By using water mixing machine wet sand can be produced.

5.Dust-proof and Environmental

Full enclosed structure prevents the dust from leaking out. With no noise nor pollutant discharge, the dust-proof is absolutely of no risk at all.

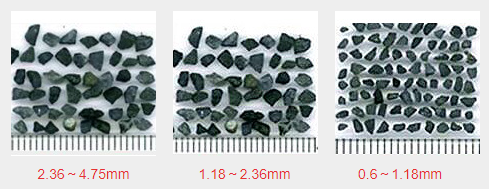

TRADITIONAL AGGREGATE MAKING

PROBLEMS

1.Coarse shape, high cost

Due to the use of cheap production of the jaw crusher, simple crushing, single screening, it makes the needle flake of coarse aggregate particles, high void ratio, the quality fluctuation significantly, which leads to a big dosage of cement mixed by concrete, higher cost.

2.36~4.75mm1.18~2.36mm0.6~1.18mm

2.Unstable quality, low capacity

After several years exploitation, the source in the river is reduced and in short supply. Then the price rises but no guarantee on the quality and supplying, Which makes the laboratory often adjust the mixing proportion, causing a big dosage of cement mixed by concrete, seriously dragging on the enterprise’s production and cost.

3.The disadvantage of existing technology

The existing technologies such as the simple crushing, the single screening, and the water dedusting have caused disqualification of the final sand. And also it is very hard to deal with the wastewater treatment.

4.The serious pollution of noise and dust.

With the more and more strict requirement of the environmental protection, a lot of factories which do not meet the requirement have been shut down by the government.

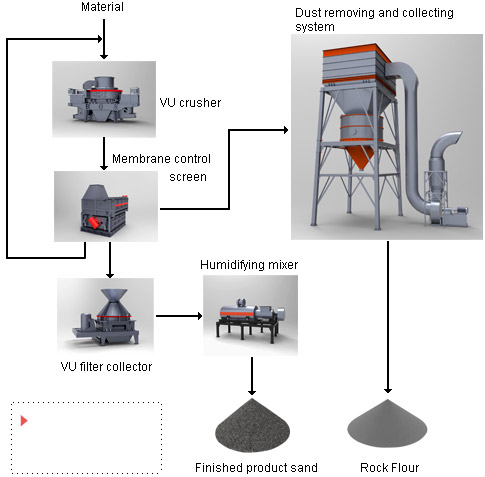

Production Process Flow

Liming VU dry process of sand and gravel aggregate system with the most reasonable, greatest degree reproduce naturally in the process of natural sand formed broken, erosion action such as friction, natural washing, make product sand performance is improved. – 15 mm raw materials (can be stone chips, pea stone and other cheap accessible raw materials such as stone) after dealing with the VU system is reasonable and efficient, reasonable distribution, grain output fruity, controllable sand powder content, as well as dry clean, can undertake unity recycled high value-added powder (determined according to the raw material can be used).

Technical Parameters

| Model | Parameter Name | ||||

| Feeding Size(mm) | Raw Material Feeding (t/h) | Capacity(t/h) | Powder Content (adjustable) | Installed Power(Kw) | |

| VU-120 | 0-15 | 90-110 | 75-95 | 3-15% | ≈780 |

| VU-150 | 0-25 | 135-150 | 110-135 | 3-15% | ≈920 |

| VU-300 | 0-25 | 270-300 | 220-270 | 3-15% | ≈1960 |

*The capacity that the table shows will change according to the change of system parameter and raw material performance.

*The moisture content of raw material should be below 3%.

*For specific conditions of the system configuration and production information, please chat with online.